Why tooling is important in the manufacturing industry Precision tooling is the process of manufacturing tools that meet specific tolerances and are intended for certain industries or uses. It helps…

Why tooling is important in the manufacturing industry Precision tooling is the process of manufacturing tools that meet specific tolerances and are intended for certain industries or uses. It helps…

As a custom plastic part evolves from a concept to reality, it may pass through multiple design stages. A 2D drawing provides the basis for creating a 3D CAD rendering…

What are the main benefits of plastic injection molding? The most cost-effective way to manufacture is by using injection molding. Other factors include the durability of plastic parts, client and…

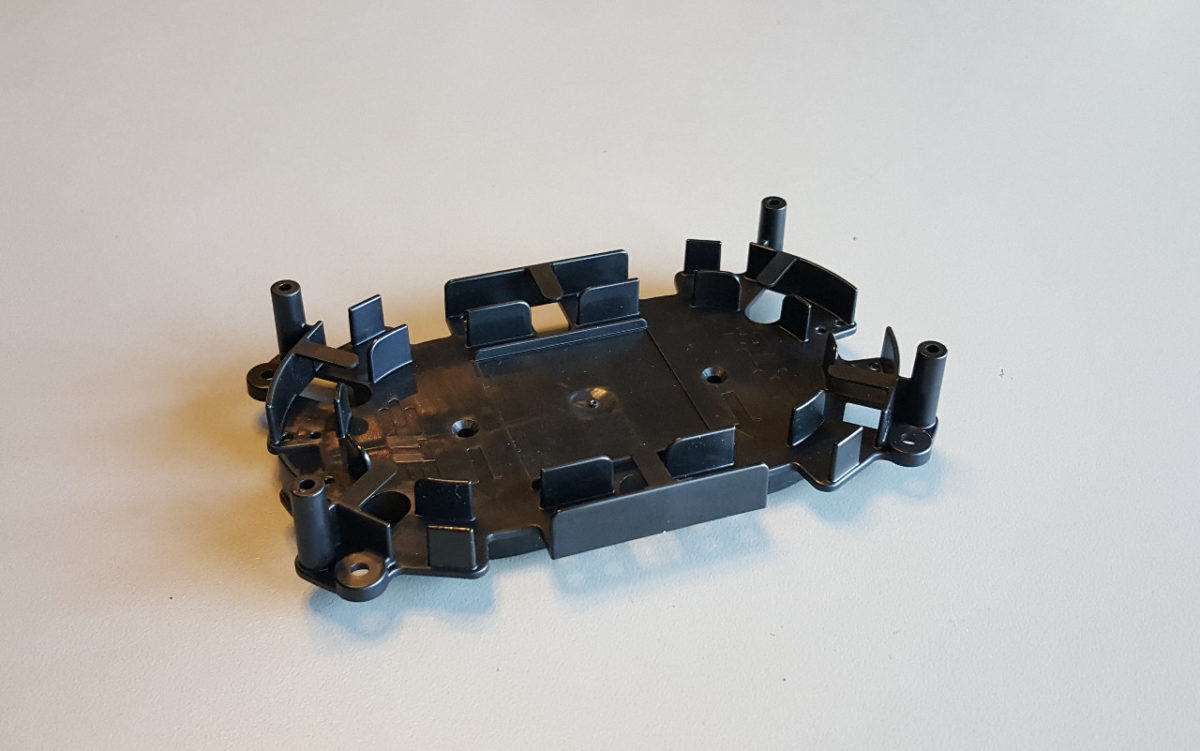

Attention to detail is key in all manufacturing. One of the most important details in injection molding is well-designed, precise and high-quality tooling. Injection mold tool is a mold or…

This process is very versatile, and it can be used to produce many different parts for various applications. You have a variety of options when creating a product requiring molded…

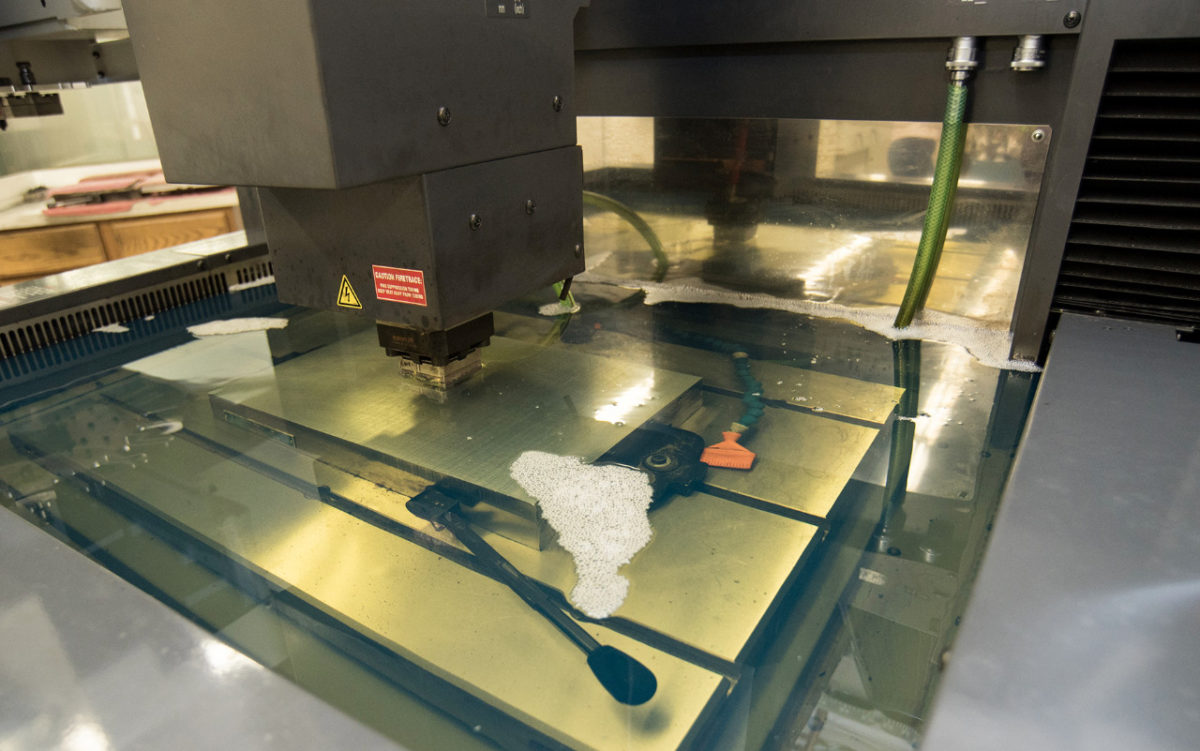

Tooling Services Plastic injection tooling involves the shaping and production of metal components that give a final shape to a product. To ensure that the mold’s core box and casting…

Injection molding is a process that can be used to create plastic parts in a variety of applications. This technique is dependent on a variety of materials and different types…

Many industries are interested in producing high volumes of precision parts. Injection molding has the greatest versatility of any molding technique.Presses are rated by size, pressure or tons.Larger machines can…

Plastics are a diverse group of materials, and the molding processes that create them can be very varied. Injection molding is a process that involves heating thermoplastic and thermosetting polymers,…

Injection molding sliders or lifters allow a part to be released from an injection mold by releasing it. Slides or sliders are used to release any external undercuts or recesses…

Recent Comments