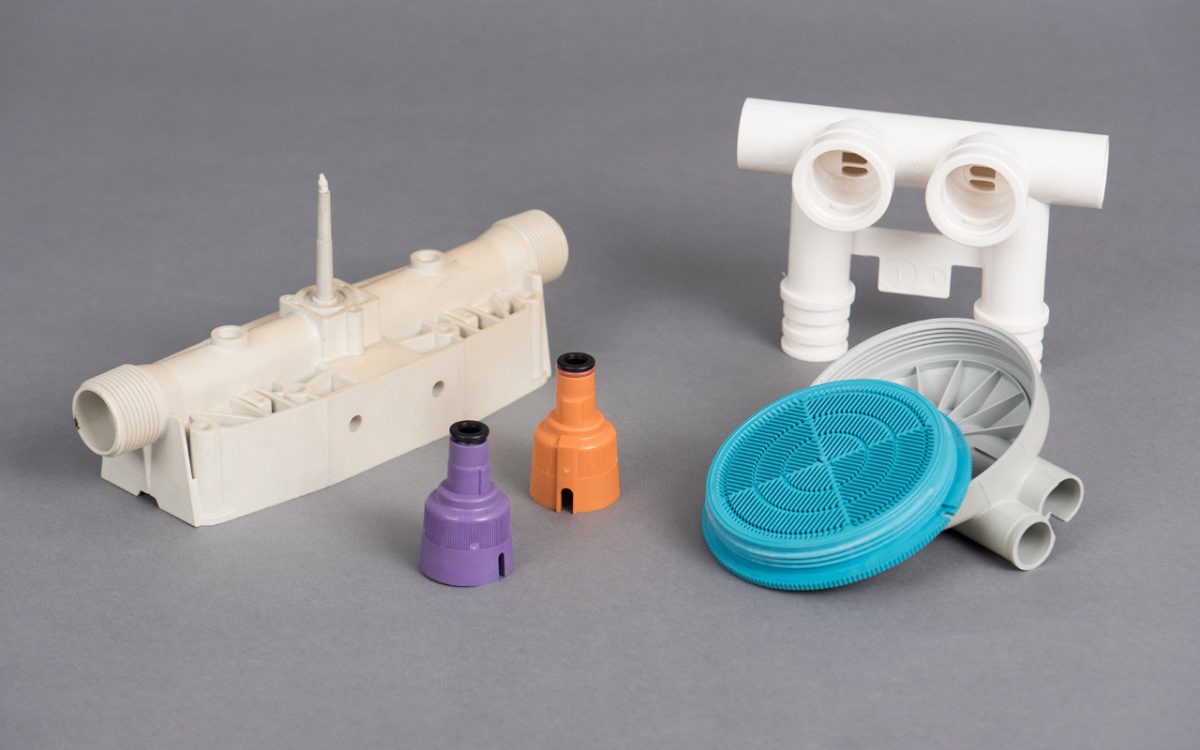

Injection molding is widely known as a high-volume manufacturing process—but it can also be used to create prototypes. At Preferred Tool, we define injection molded prototypes as several hundred to…

Injection molding is widely known as a high-volume manufacturing process—but it can also be used to create prototypes. At Preferred Tool, we define injection molded prototypes as several hundred to…

Custom molds are essential in numerous industries for a wide range of applications. When designing a mold, it’s important to partner with a company that listens to your specifications and…

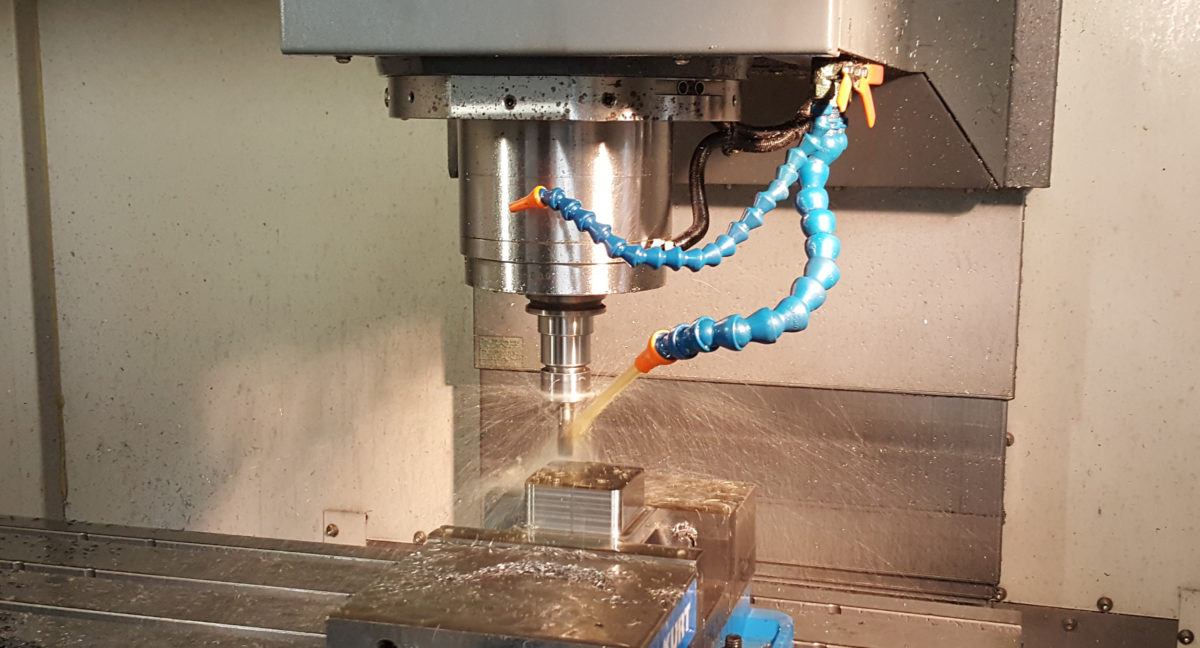

Plastic injection molding is a widely used and efficient method of manufacturing parts in large quantities. It’s recognized for its ability to produce highly precise and accurate parts at a…

Custom molds are an integral part of many industries, from manufacturing and automotive to food production and medical equipment. No matter the industry, getting the mold design right is critical….

Plastic injection molding is one of the most widely used methods for producing plastic parts, and for good reason. It offers numerous advantages over other plastic molding methods, making it…

Custom molds are essential across various industries for different applications. To ensure that the mold meets your exact needs, it’s important to partner with a company that pays close attention…

Advantages and Disadvantages of Injection Molding Efficient High Production Speed: Injection molding is highly efficient, especially after molds are developed. Cycle times can be as short as 10 seconds. Volume:…

As a custom plastic part evolves from a concept to reality, it may pass through multiple design stages. A 2D drawing provides the basis for creating a 3D CAD rendering…

Recent Comments