Custom molds are an integral part of many industries, from manufacturing and automotive to food production and medical equipment. No matter the industry, getting the mold design right is critical. A well-designed mold ensures efficiency, precision, and quality in the final product. To achieve this, the collaboration between you and the mold manufacturer is key, ensuring the process runs smoothly and the mold perfectly meets your needs. For all of your custom mold needs contact Preferred Tool located in Hugo Minnesota serving all of Minnesota and Wisconsin.

Step 1: Understanding Your Tooling Requirements

Before diving into the manufacturing phase, it’s essential to have a clear understanding of your tooling requirements. This first step helps the mold manufacturer assess the complexity of your project and provide an accurate quote. To assist in this, you will likely need to supply detailed specifications or designs that outline the mold’s purpose and function.

Upon reviewing these requirements, the manufacturer will offer you a quote. If the proposed cost fits your budget, the process moves forward. However, if it exceeds your budget, don’t worry—there are often ways to make adjustments or explore other providers who may offer competitive pricing. During this stage, it’s important to balance quality and cost to ensure you’re getting the best value for your investment.

Step 2: Design Review with CAD Software

After agreeing on the price, the next step involves reviewing the design using cutting-edge Computer-Aided Design (CAD) software. Modern CAD tools allow mold designers to create highly detailed, accurate representations of the mold, making it easier to visualize your idea in three dimensions.

This step is where your active participation becomes vital. You’ll need to carefully review the design, paying close attention to every detail—no matter how small. Once you give your approval, the design will be sent directly to the manufacturing team, and further changes can be difficult or even impossible to make without additional costs and delays. Therefore, taking the time to thoroughly inspect the design at this stage is crucial.

Step 3: The Manufacturing Process Begins

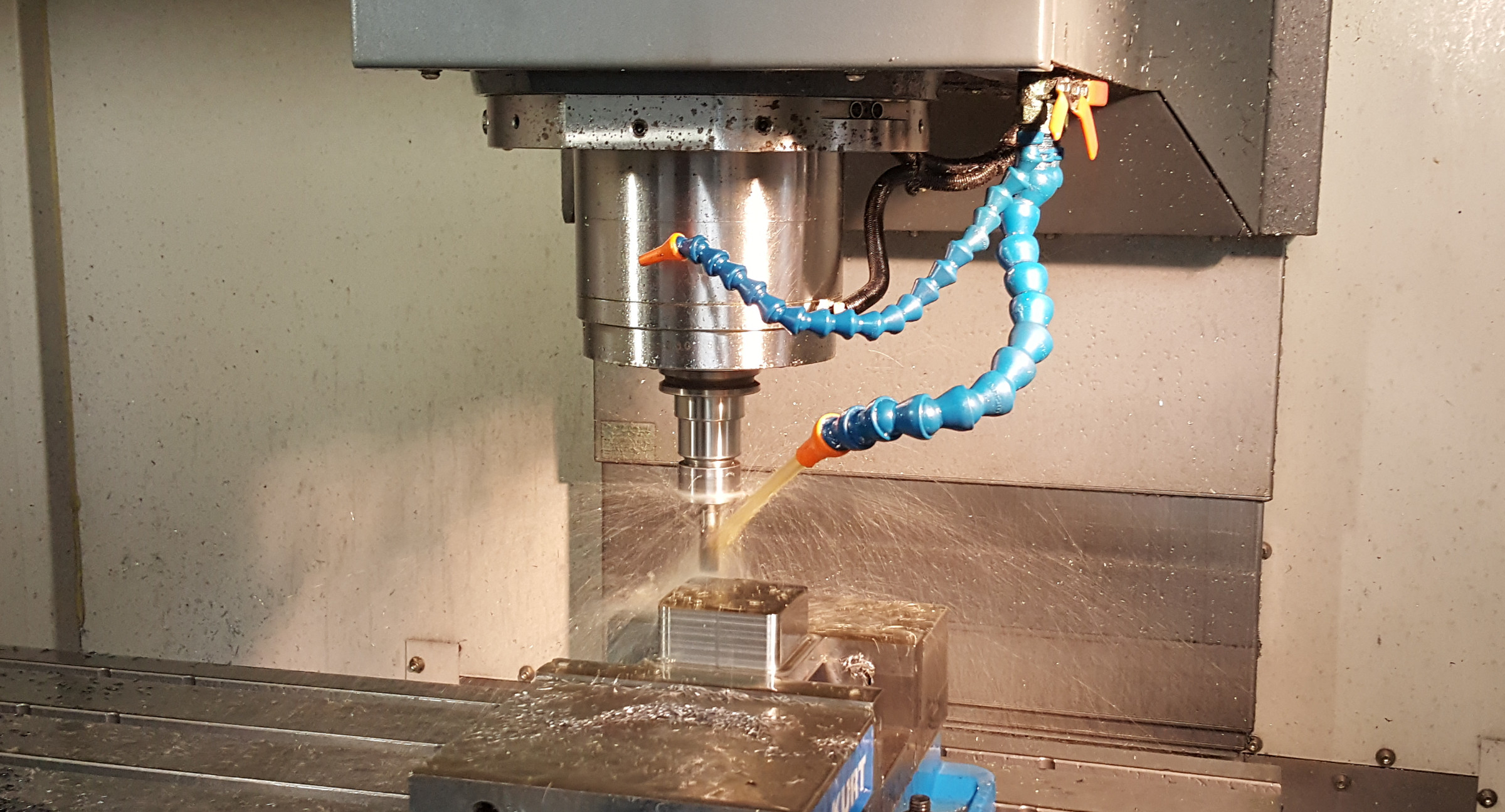

Once the design has been confirmed and approved, the manufacturing process kicks off. At this point, the professionals take over, using their expertise and experience to bring the design to life.

This stage requires a lot of concentration, precision, and attention to detail. Every aspect of the mold is carefully crafted to match the design specifications perfectly. Depending on the complexity of the mold, this process can take varying amounts of time, but rest assured that the mold makers will work meticulously to ensure high-quality results.

Step 4: Final Inspection and Quality Check

After the mold has been manufactured, it undergoes a thorough inspection to ensure it complies with all required standards and aligns exactly with the design you approved in Step 2. This includes checking dimensions, surface finishes, and functionality to ensure the mold is capable of delivering the results you expect.

At this point, the manufacturer might also run some test samples to verify that the mold performs as intended. Once everything has passed the final quality checks, your mold will be packaged and shipped to your location.

Why This Process is Important

The mold design and manufacturing process outlined above is essential for ensuring that you, as the customer, remain engaged and informed every step of the way. It’s not a matter of handing over your concept and waiting for the final product; instead, there is constant collaboration and feedback to prevent any issues or misunderstandings. This ensures that when your mold arrives, it meets all your expectations and is ready to perform its intended task.

Skipping these steps or working with a provider who does not follow a detailed process can lead to significant issues down the line. You might end up with a mold that doesn’t perform correctly or needs to be sent back for costly redesigns and modifications. To avoid this, it’s crucial to choose a manufacturer who prioritizes customer communication, attention to detail, and quality control.

Why Choose Preferred Tool?

At Preferred Tool serving the entire Twin Cities, Minnesota, we strictly adhere to these step-by-step procedures to ensure every mold is crafted with precision and care. Customer satisfaction is our top priority, and we make sure that you are fully involved in the design process. From the initial quote to the final delivery, we maintain open lines of communication to ensure your needs are met.

When you choose Preferred Tool located in Hugo, Minnesota, you’re not just getting a mold—you’re getting a collaborative partner committed to making your project a success. We sit down with you, go over the design in detail, and keep you informed every step of the way to ensure your mold turns out exactly as you envision it.

If you need a custom mold for your next project, contact us today!