Custom molds play a crucial role across countless industries—from automotive and medical to consumer goods and electronics. But creating the right mold for your project isn’t just about machinery; it’s…

Custom molds play a crucial role across countless industries—from automotive and medical to consumer goods and electronics. But creating the right mold for your project isn’t just about machinery; it’s…

Injection molding is widely known as a high-volume manufacturing process—but it can also be used to create prototypes. At Preferred Tool, we define injection molded prototypes as several hundred to…

When creating products with molded plastic components, manufacturers have a variety of options depending on the application and the type of part needed. Among these, injection molding stands out as…

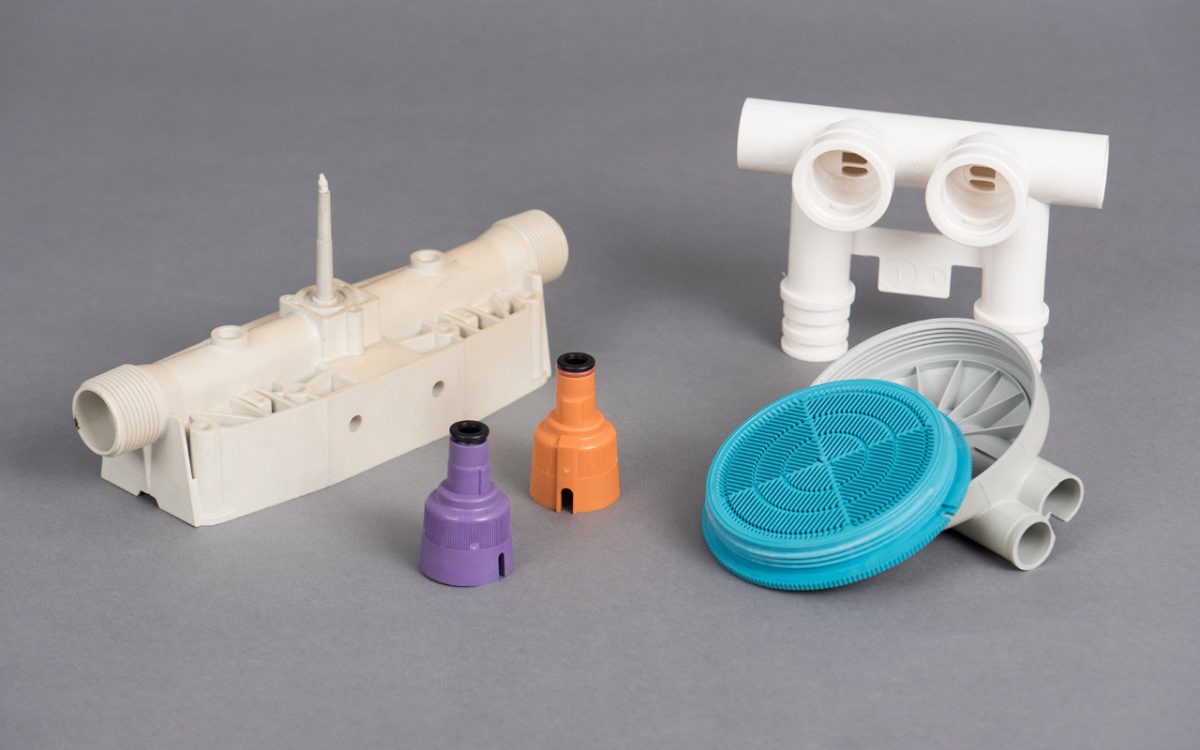

Custom molds are essential in numerous industries for a wide range of applications. When designing a mold, it’s important to partner with a company that listens to your specifications and…

Metal Injection Molding (MIM): A Versatile Manufacturing Process for Intricate Metal Parts Metal Injection Molding (MIM) is an advanced manufacturing method that allows for the creation of small, complex metal…

Plastic injection molding is one of the most widely used methods for producing plastic parts, and for good reason. It offers numerous advantages over other plastic molding methods, making it…

Custom molds are essential across various industries for numerous applications, from creating intricate parts to producing large-scale products. When it comes to designing a custom mold, it’s crucial to work…

Why tooling is important in the manufacturing industry Precision tooling is the process of manufacturing tools that meet specific tolerances and are intended for certain industries or uses. It helps…

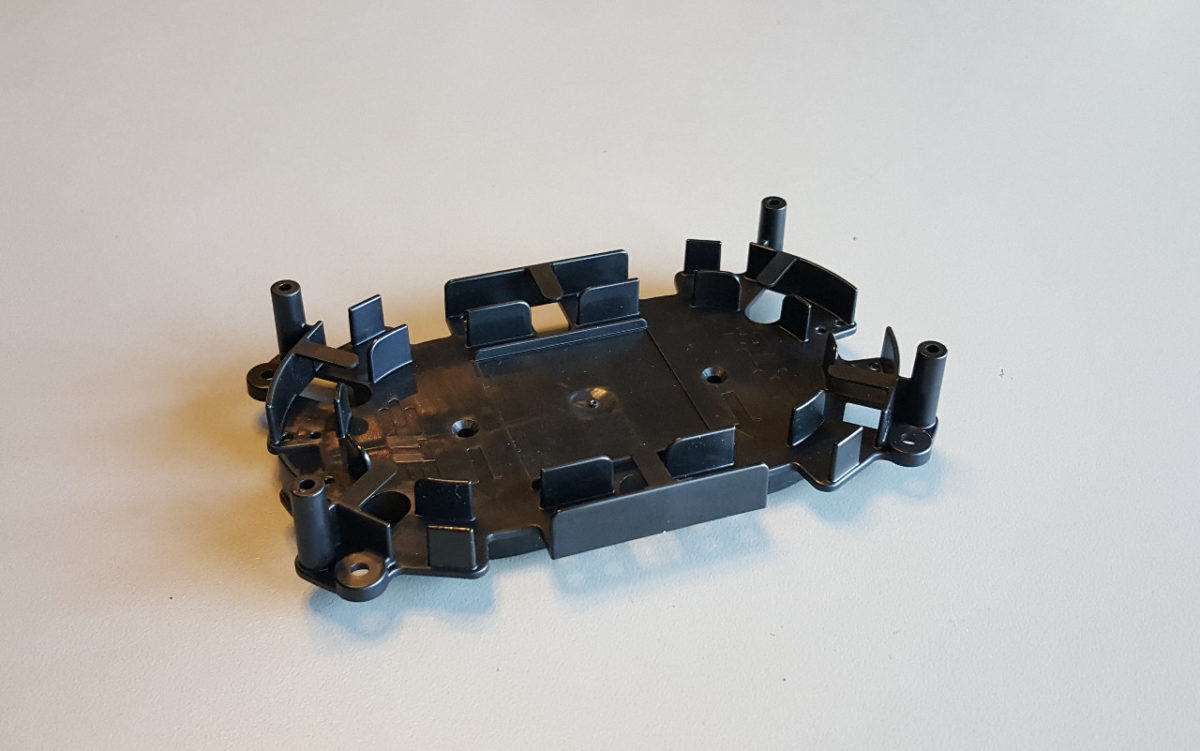

As a custom plastic part evolves from a concept to reality, it may pass through multiple design stages. A 2D drawing provides the basis for creating a 3D CAD rendering…

What are the main benefits of plastic injection molding? The most cost-effective way to manufacture is by using injection molding. Other factors include the durability of plastic parts, client and…

Recent Comments