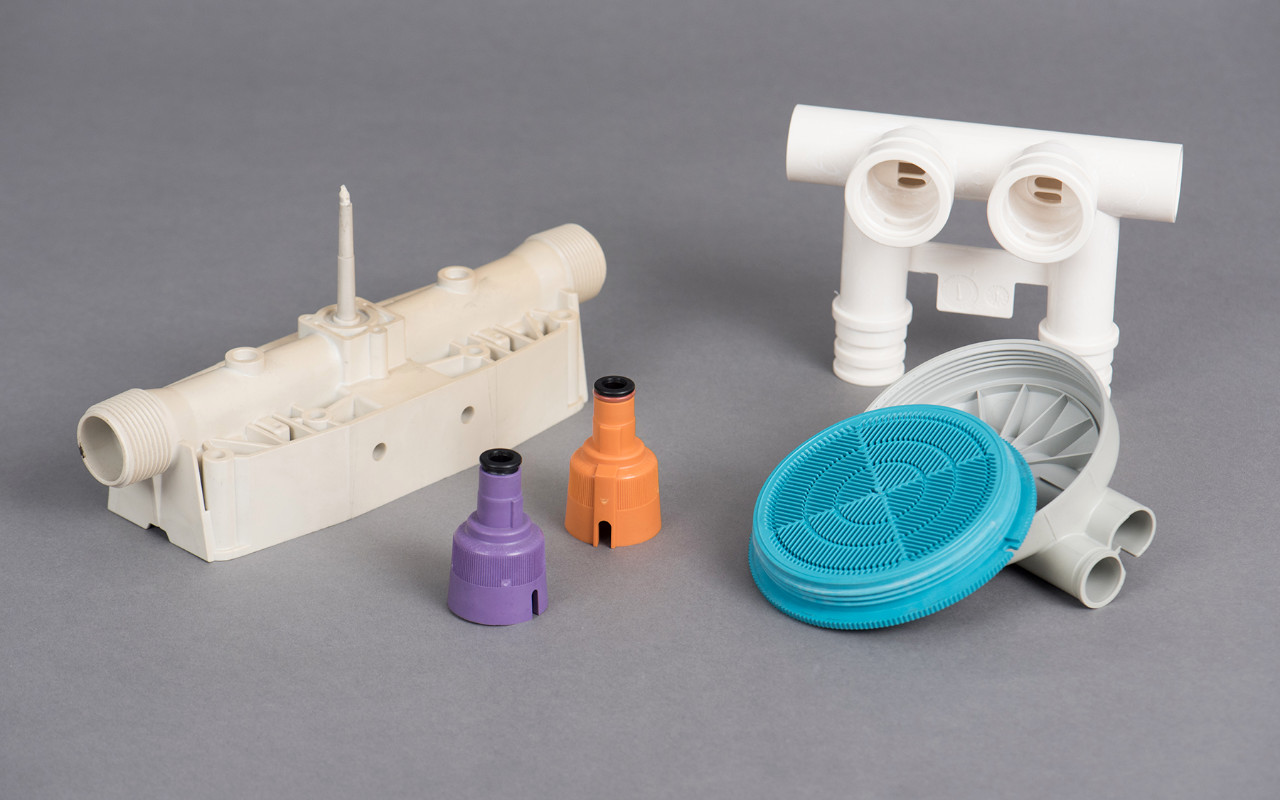

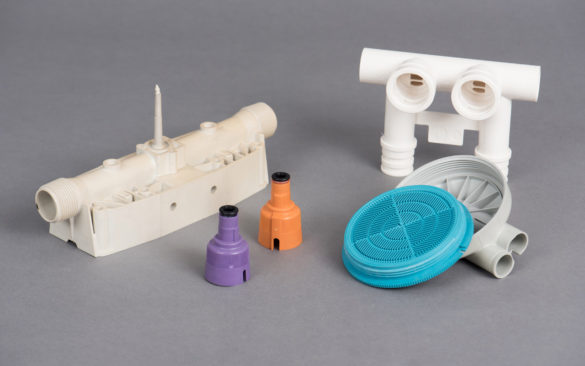

Plastic injection molding is a highly versatile method that is used to produce parts and products and is among the most preferred methods for manufacturing parts due to the many advantages it has over other plastic molding methods. Apart from being simpler and more reliable, plastic injection molding is very efficient.

Plastic injection molding is a highly versatile method that is used to produce parts and products and is among the most preferred methods for manufacturing parts due to the many advantages it has over other plastic molding methods. Apart from being simpler and more reliable, plastic injection molding is very efficient.

If you are looking for the best method to manufacture parts, consider plastic injection molding. That said, here are the top 5 benefits of using plastic injection molding process to manufacture plastic parts and components:

1.Detailed Features and Complex Geometry

The injection molds are usually subjected to very high pressure. This causes the plastic in the mold to be pressed harder against the mold than other processes of molding. This very high pressure makes it possible to add more details into the part’s design.

The high pressure also makes it possible to design and manufacture complex and intricate shapes that would be expensive and complicated to manufacture.

2. Highly Efficient

Once the injection molds are designed to the customer’s specifications and the presses are pre-programmed, the process of molding will be quicker than other molding methods. This process does not take too much time hence enabling more parts to be manufactured from a single mold. Plastic injection molding is highly efficient and more cost-effective because of its high production output rate.

Hot-runner ejection mold systems usually produce consistently high-quality parts at faster cycle times. However, it is not as easy to change colors or can hot runners be able to accommodate some polymers that are heat-sensitive. Find out more about the major differences between hot-runner and cold-runner systems.

3. Adds Greater Strength to The Molded Part

Fillers in the injection molds can be used in plastic injection to add greater strength to the part that has been molded and reduce the density of the plastic while it is being molded. Plastic injection is usually the only option in fields where parts should be strong and durable as it has an option that is not offered by the other molding processes.

4. Can Use Many Types of Plastic Simultaneously

Among the top benefits of using plastic injection molding to manufacture parts is the fact that it can use different plastic types simultaneously. This can be done alongside co-injection molding which ensures that you don’t have to use a certain type of plastic.

5. Reduced Manufacturing Costs

Plastic injection molding process is automated. Most of the injection molding process is done by robotics and machines that can be controlled and managed by one operator. This automation reduces manufacturing costs as it significantly reduces the overheads. Besides, the reduced labor force reduces the overall cost of manufacturing the parts. The reduced cost can be easily passed to the customer.

Moreover, automation ensures that the injection molds are made precisely and accurately. Computer aided manufacturing (CAM) and computer aided design (CAD) allow close tolerances when the molds are being made.

The Bottom Line

Parts manufactured using injection rarely need any work after their production as the parts have more or less a finished appearance when they are ejected from the injection molds. Nowadays, plastic injection molding is an eco-friendly process as the scrap plastic produced during the production process is reground and re-used. This means that the entire process produces very little waste and this is what makes it eco-friendly.