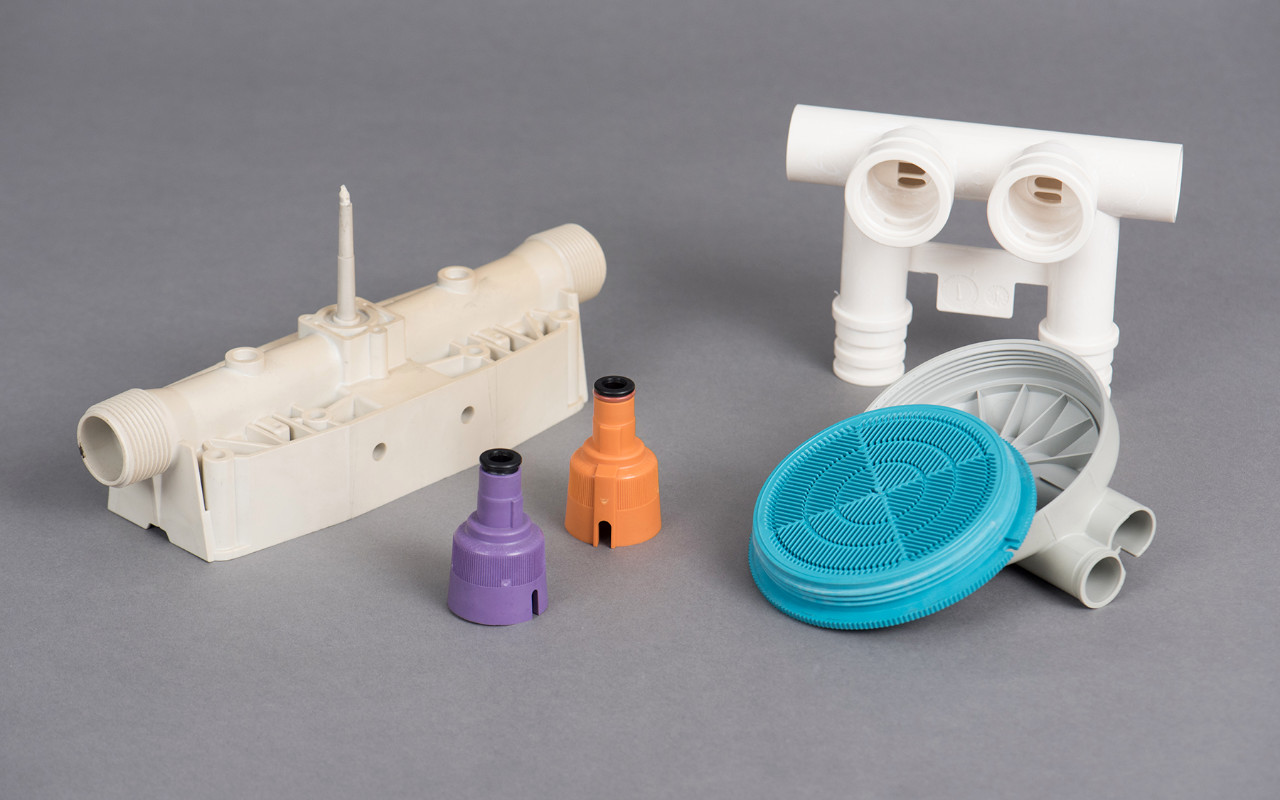

Plastic injection molding can be used to produce many parts. It offers many advantages over other methods of plastic molding. It is more reliable, simple, and efficient than other methods and it is also very cost-effective.

Let’s look closer at six of the most important benefits this process offers:

1. High efficiency and fast production

Plastic injection molding is a popular type of molding because of its efficiency and popularity. The process is much faster than other methods and produces a high level of output, which makes it more economical and efficient. The size and complexity the molds affect the speed. Between each cycle, however, only 15 to 120 seconds’ pass.

Because the time between cycles is so short, molds can be made in a shorter time which results in increased revenue and profit margins.

2. Part Design Complex

Injection molding can handle complex parts. It also allows for uniformity and the ability to make millions of identical parts. Critical design elements are necessary to maximize the efficiency of high-volume injection molding and to increase the quality and precision in your parts. To maximize the efficiency of high-volume injection molding, it is important to design your part. The right design will allow you to produce high-quality parts on a regular basis. Poor design can lead to costly processing mistakes.

Molding professionals across the industry agree that there are some fundamental design elements that must be present during the injection process to ensure it works properly. These include proper placement of vents, gate positioning, weld lines and corner transitions.

3. Enhanced Strength

When designing a plastic injection-molded part, strength is a key factor. Designers must determine if the part should be stiff or flexible to allow for adjustments to the integrating gussets and ribs. Another important aspect is to understand how customers will use the part and the environment in which it will be placed.

The right combination of design considerations can be used to meet the requirements of the part’s stability and strength. The part’s strength is also affected by the material selection. Below is more information about the types of resins used in this process.

4. Flexibility – Colors and Materials

When creating plastic parts, it is important to choose the right color and material. Both have so many possibilities. The availability of a variety of resins has increased over the years due to advances in polymers. It is important to work with an injection molder who has experience with different resins and applications, including those that comply with FDA, REACH, RoHS, RoHS, NSF, REACH, RoHS and RoHS. The following factors should be considered when choosing the right resin for your project: water absorption and heat deflection, flexural modulus, tensile, impact, and flexural modulus.

There are many options for coloring plastics. Each system has its unique benefits and drawbacks. Pre-colored resins are used most often, along with salt and pepper mixtures, liquid color, and masterbatches.

5. Reduced waste

It is important to look at the company’s green manufacturing initiatives when looking for a high-volume injection mold company to partner with. They signify a commitment towards sustainability, quality and safety. There is an excessive amount plastic generated during the molding process. Look for companies that have a recycling system. The most eco-friendly plastic injection molding companies use state-of-the art machinery to reduce transportation, waste, packaging, and packaging.

We are committed to promoting environmental sustainability in everything we do. Over the years, we have implemented many green initiatives that have allowed us to become one of the most sustainable companies in the injection mold industry.

6. Low labor costs

Plastic injection molding is typically cheaper than other types of molding. It is possible to produce parts at a high output rate and with high quality, which helps in cost-efficiency and effectiveness.

Molding equipment is typically equipped with an automatic, self-gating tool that keeps production going and makes operations efficient with little supervision.