Considering injection molding is the most popular method for producing plastic parts on earth, it makes sense that the global market for the process was valued at almost 260 million U.S. dollars, with projections for continued growth in the near future.

Considering injection molding is the most popular method for producing plastic parts on earth, it makes sense that the global market for the process was valued at almost 260 million U.S. dollars, with projections for continued growth in the near future.

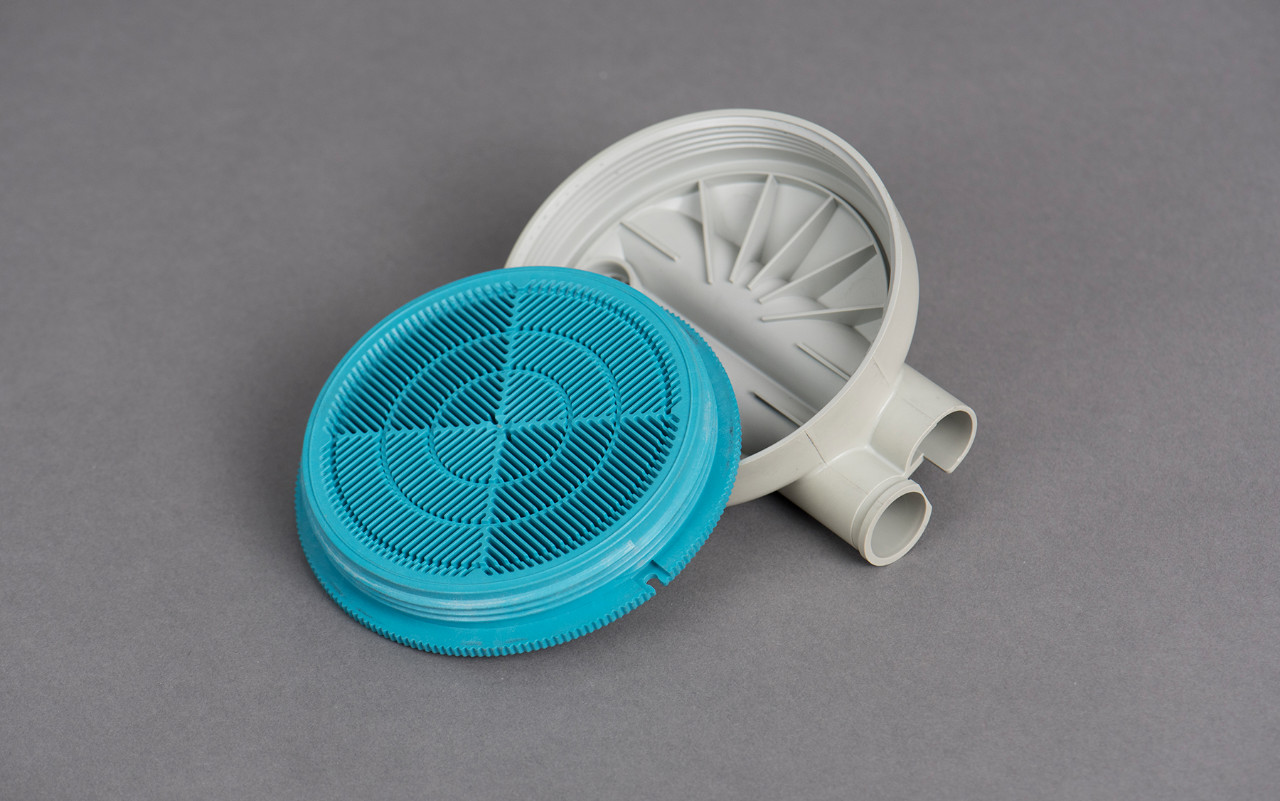

Overmolding and insert molding can be used to create even the most complex parts with perfect precision in a wide variety of industries, including aerospace, medical equipment, and automotive.

When you consider all the advantages of injection molding, you can understand why it is used by millions of companies in some of the most demanding industries in the world.

Why is injection molding machine manufacturing so effective? What is the process?

So, let’s dive into the topic and find out what it is, how it works, its main advantages, and how to choose a service provider.

What is Injection Molding?

A wide variety of parts and items can be manufactured using injection molding. Although this process has been around since the 19th century, it remains one of the most cost-effective methods of manufacturing complex parts.

To create identical copies of the product, the injection molding machine uses molds made according to specifications, using molds to fill them out according to specifications.

The flexibility of injection molding makes it a popular choice in a wide range of industries with quite different goals and needs.

These flexible advantages enable injection molding machine manufacturing to be used to produce parts in areas such as aerospace, medicine, and the automotive industry.

You can use injection molding to create small quantities of parts for testing or to make large quantities of plastic parts in a hurry, especially if you are working with plastics.

Additionally, the unique process associated with a machine for injection molding also makes it possible to create complex parts with intricate designs, something that cannot be said about all the other manufacturing options available.

Due to its ability to produce large quantities of parts at an affordable cost, it is ideally suited for the production of various commodities. You probably have a number of things in your home that were probably made by injection molding.

Applications of Injection Molding

Precision and cost-effectiveness are two of the most important considerations most companies look for when producing parts.

Because of this, it’s not surprising that a process like injection molding has become so popular and has been used to produce components with tight tolerances in both small and large runs.

Our discussion of high-tech industries has already discussed some of the uses of this manufacturing technology. Now let’s see a few more of the common items you can make using this technology.

Food & Beverage

Injection molding allows companies to produce parts from a wide range of materials, as we mentioned earlier. An industry such as food & beverage needs to comply with a variety of regulations regarding the safety of food containers, which is why it is so important. Plastics can be used in injection molding that are BPA-free and non-toxic so that they can be used in contact with food and withstand temperature changes.

The benefits of injection molding, combined with the relatively low production cost, make it a good choice for parts such as beverage caps, food containers, and filters.

Construction Parts

A third industry that uses injection molding is the building and construction industry, where plastic parts that are custom-made and complex are very important during the building process.

Furthermore, these parts often have to meet strict requirements in terms of quality and fit.

As an illustration, when creating plastic window and door parts, the parts must be not only perfectly shaped, but also durable and possess unique properties that allow them to withstand weather elements.

It provides excellent performance at a much lower cost than metal components, so injection molding is used even today to produce parts that can replace metal components.

Medicine

Medical companies can now produce essential tools and parts more cheaply due to injection molding, which makes healthcare more accessible throughout the world.

It is the precision of injection molding that makes the field of medicine so indispensable. Heart pumps, monitors, and a variety of medical instruments all rely on injection molding in some way.