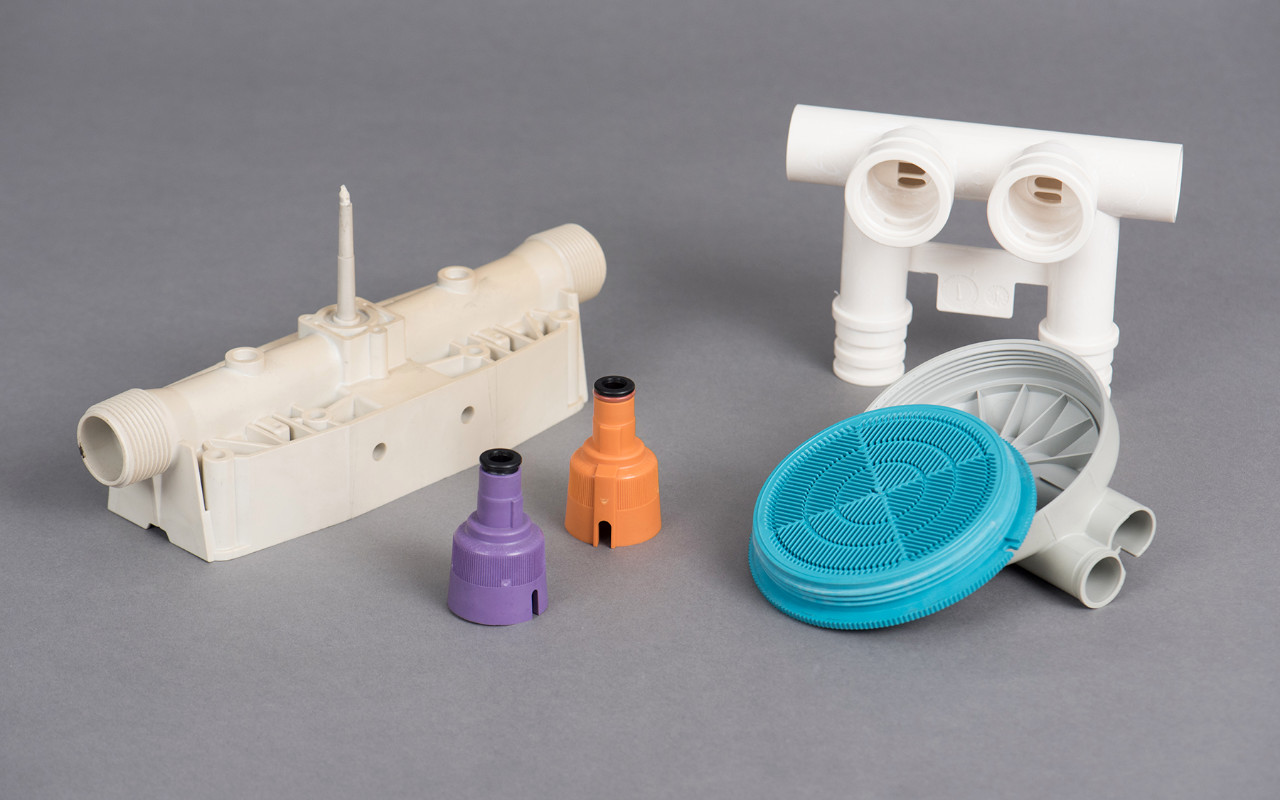

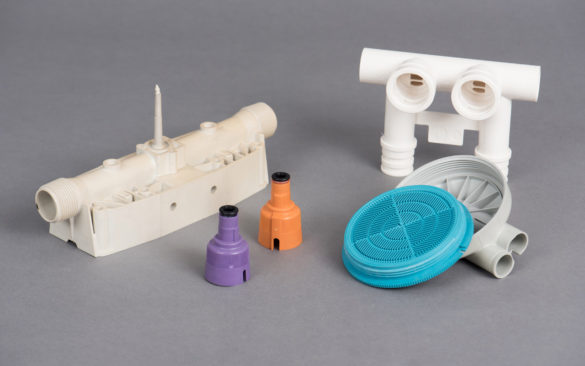

There are many applications where high-quality injection molds can be used, and we can make custom molds for almost all of them. At a low per unit cost, clients can make scale custom plastic parts by using these molds.

There are many applications where high-quality injection molds can be used, and we can make custom molds for almost all of them. At a low per unit cost, clients can make scale custom plastic parts by using these molds.

Plastic injection molding is used to make lots of items that are used every day, such as car parts and even toys. Why is injection molding so widely used? Due to its high efficiency and low waste production, injection molding is perfect for anyone who wants to create simple or complex plastic parts on a wide scale.

What is the process behind plastic injection molding?

Injection molding allows for high quality products and parts to be created with speed and efficiency by manufacturers. This is done by injecting liquid metal or plastic into molds with the help of a molding machine, which results in a product being produced. When injection molding is used, it is possible to quickly create many pieces at once.

The necessity for large production numbers, such as 100 or more pieces, usually results in a producer needing to use injection molding. A low unit cost, along with other advantages, are available with injection molding. Many products that are used everyday are produced in great numbers with injection molding. You’re probably even using something that was produced with the help of injection molding at this very moment. Plastic injection molding has become important for our lives, as it results in the production of car parts, computer mice, and everything else that we think of as necessary.

Steps involved in the injection molding process

1. Melt plastic

2. Put molten plastic into mold via injection

3. Allow the molten plastic to cool until it becomes solid

4. Take the solidified product out of the mold

Controlling the injection molding process

Certain processes must be taken into account and put under control in order to produce molded products of a high quality.

Temperature has a major importance in injection molding, as it affects the performance of the mold and the entire process. Careful adjustment must be made to products because plastic materials will melt at different points.

In the mold cavity and the injection process, pressure must also be controlled and monitored. If the pressure isn’t great enough, an incomplete product will be produced. Material will be forced out of the mold if the pressure is too great.

Custom injection molding advantages

The material used for the creation of plastic parts through injection molding is an important factor. Many types of plastic exist, and they all come with their own unique strengths and properties.

These plastics can have the ability to resist chemicals, resist abrasion, and handle certain temperatures. There is essentially a plastic for every kind of situation.

Preferred Tool Custom Injection Molds.

Clients who use Preferred Tool will be able to receive custom products from a company with years of experience. We’re ready to work with you if you need to use custom injection molding for your project. Contact us here or give us a call.