Plastic injection molding is among the most widespread technological processes of today. Manufacturers of all categories of products use plastic injection molding, due to its significant benefits that help them keep their production costs under control. Here are a few of the benefits of this method:

Plastic injection molding is among the most widespread technological processes of today. Manufacturers of all categories of products use plastic injection molding, due to its significant benefits that help them keep their production costs under control. Here are a few of the benefits of this method:

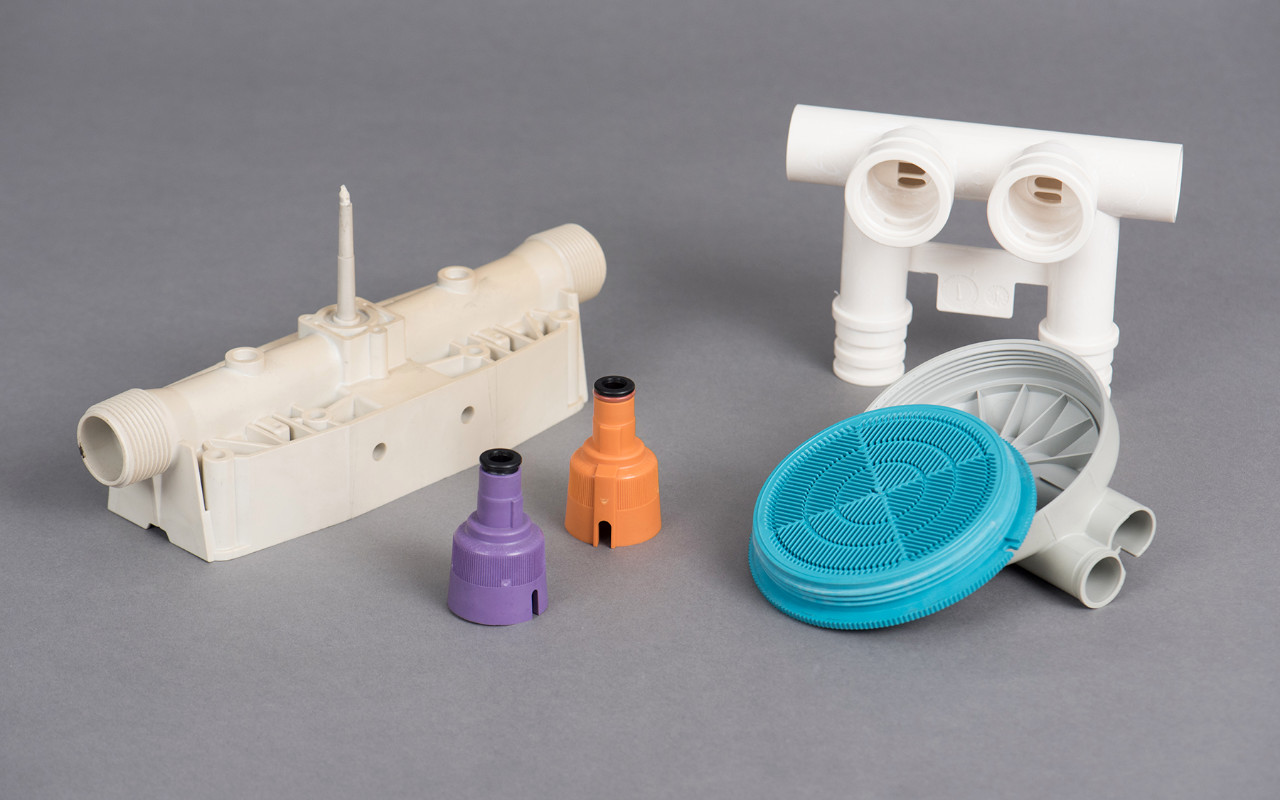

1. Shape Versatility

Injection molding is the ideal choice in a wide array of projects. It allows manufacturers to create basic items, as well as complex structures with intricate details. Obtaining such parts by using other technological processes and manufacturing methods would be extremely complicated, if not impossible in some cases.

2. Production Efficiency

As soon as you’ve created your mold, you can start your manufacturing process. Injection molding suits mass production of various parts. The reason is that the production time is of only 15-30 seconds, much shorter than in case of other manufacturing technologies and methods. Furthermore, by using a multi-cavity mold, you can make multiple parts at the same time. For instance, you can manufacture both the top and the bottom of an enclosure at the same time.

3. Excellent Flexibility And Durability

You can use a wide range of resins and standard materials to manufacture injection molded parts. Based on the required characteristics of your product, you can create its different parts from different materials, thus securing the flexibility and the durability you need. By adding fillers to the resin mix, you can increase the durability of various elements without making them heavier.

4. Wide Choice Of Resin Materials

One of the biggest advantages of injection molding is that it allows you to use multiple types of resins at the same time, during the same production process.

5. Automation

Injection molding is mainly an automatic process. Thanks to modern CAD tools and software, you can automate your production processes without compromising on the accuracy of the end result. Unlike other production methods, injection molding allows you to maintain tight tolerances.

6. Complex Aesthetics

Since injection molding allows you to use different materials for different parts of an item, you can create elements with complex textures and different aesthetics. All we need to do is to texture your mold with the desired finish.

7. All Benefits Work To Your Advantage

Once the injection molding process is complete, you won’t require too much additional work to finish your products.